Industry-news

Points for attention in construction of fiberglass mesh fabric

Points for attention in construction of fiberglass mesh fabric

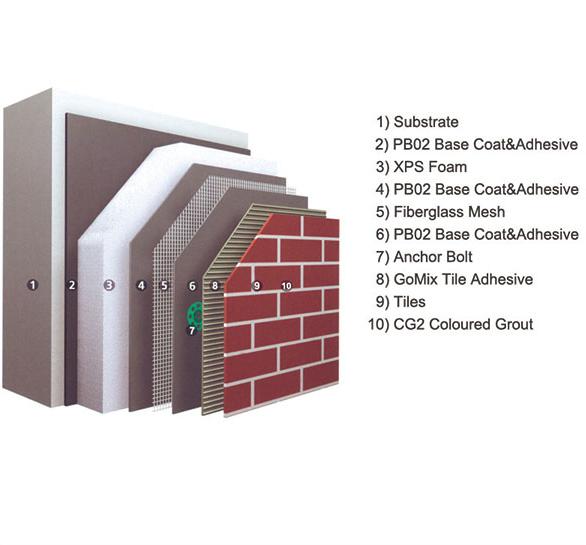

Base cleaning → watering and wetting → scraping the bottom layer of plain slurry → laying grid cloth → scraping surface layer of plain slurry → watering and curing

1. Base cleaning the accepted wall surface dust, sundries and so on clean up, concrete bulging chisel and processing flat.

2. The wall should be moistened by water one day before the construction. It is advisable to immerse the wall with water 8 ~ 10mm. In case of air-dry weather, the wall should still be dry and not wet when plastering. The wall should be sprayed with water again before the construction.

3. Scrape the bottom layer of plain cement slurry mixed with 107 glue, scrape evenly on both sides of the wall of different materials with iron spreader, each side is not less than 150mm, the thickness is about 2 ~ 3mm, the bottom layer of plain slurry should be even and not reveal the base layer, the grid cloth is then laid and pasted.

4. Lay grid cloth will be cut in advance grid cloth tension on the already scraped bottom layer pulp, with iron scraping pressure into the bottom layer pulp, leaving no wrinkles, grid cloth on both sides of the straight and uniform width.

5. After the mesh cloth of the scraping layer is paved and smoothed, the mesh cloth shall be smeared with the cast iron cement slurry, and the mesh cloth shall not be exposed.

6. When the grid fabric is glued, if it can not be plastened immediately, after 12 hours, sprinkle water to keep the surface wet, the curing time is not less than 3 days.

Expansion data:

(1) according to the design requirements, the ink line is used to eject the horizontal line 20mm away from the water mark height on the surface of the flat external wall. When the system deformation slot is needed, the deformation slot and the width line should be ejected at the corresponding position on the wall surface, mark the bonding position of EPS board, and should be according to the distribution of holes in the wall for EPS Board Row, on the base elastic line.

(2) EPS board should be cut by electric wire cutter, standard panel ruler is 1200mm * 600mm, the allowable deviation should meet the following requirements, the size should be vertical.

(3) before pasting the EPS board, the line should be hung according to the requirements of flatness and verticality, and the first step is to turn over the package or wrap the edge of the starting terminal of the system.

(4) when the decorative surface of the first floor needs to be covered with tiles, the angle steel bracket should be installed first, and the wall should be connected with the expansion bolt. Each bracket shall be equipped with not less than Φ80 expansion bolts embedded in the wall body not less than 50mm.

(5) the point bonding method should be used in the EPS board bonding. The stainless steel trowel is used to smear 50mm wide and 10mm thick adhesive mortar belt along the periphery of the EPS board. When standard size EPS board is used, 8 bonding points should be evenly arranged in the middle of the board surface, each point has a diameter of 100-150 mm, mortar thickness of 10 mm, center distance of 200 mm. When non-standard size EPS board is used, the smearing area of the middle part of the board shall not be less than 35% of the area of the EPS board, and the above ratio shall not be less than 40% when the first layer.

Ganzhou Wolfe Trading Co. , Ltd. is a large Chinese manufacturer and exporter of fiberglass and its products, our main products are fiberglass yarn, fiberglass mesh cloth, fiberglass industrial cloth, fiberglass self-adhesive tape, fiberglass fire blanket, fiberglass-covered aluminum foil self-adhesive cloth, etc. , welcome Chinese and foreign customers to negotiate procurement.

Address: Shangyou County Industrial Park, Ganzhou, Jiangxi province

Tel: 13979783338(Mr. Fang) Website:www.gzwef.com E-mail:fangyulai@163.com

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Fang

Mobile:8613979783338

Tel:8613979783338

Whatsapp:8613979783338

Email:fangyulai@163.com

Add:North Industrial Park, Shangyou County, Ganzhou, Jiangxi,China